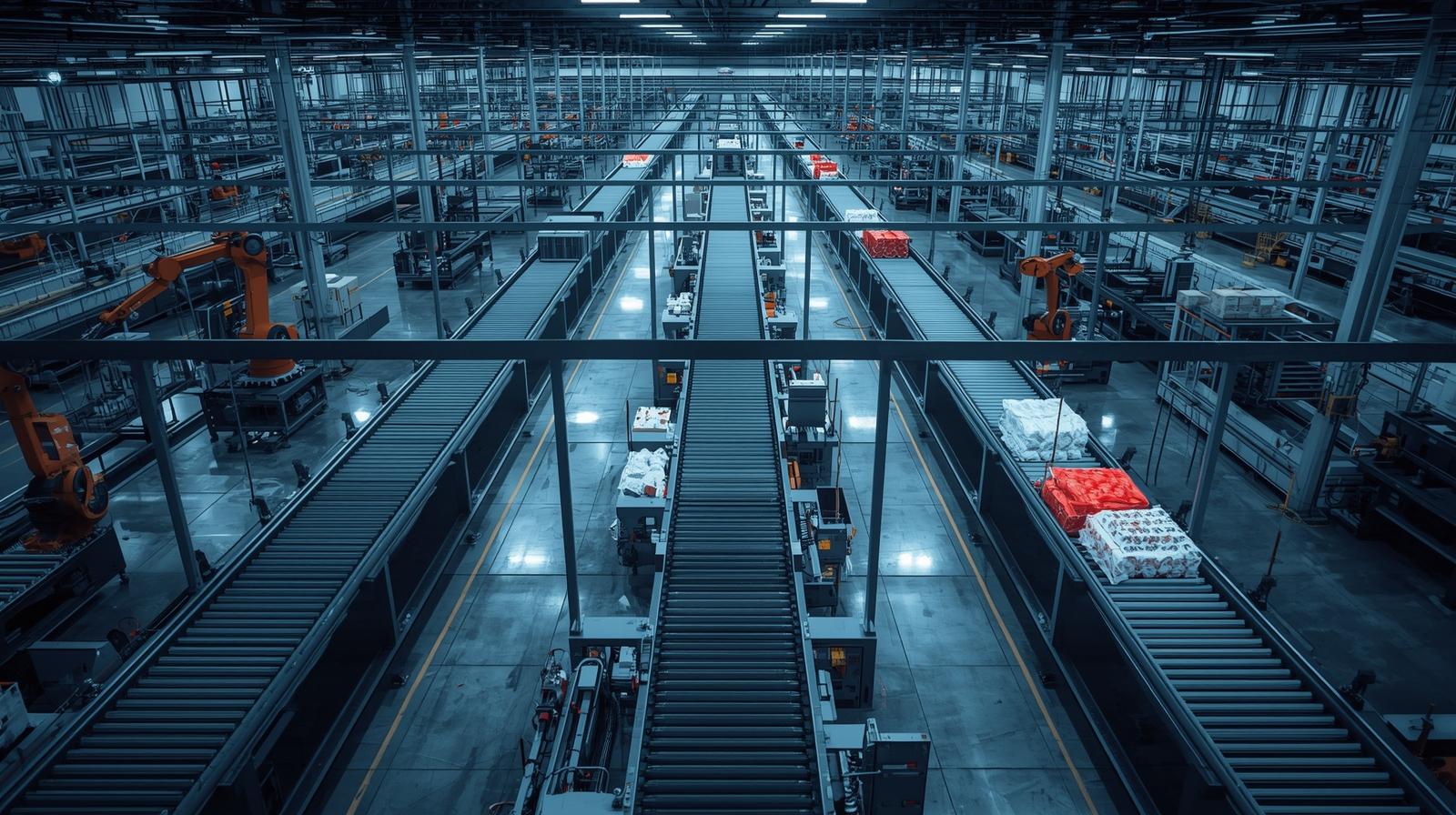

Plastics Industry

The plastics industry involves processes such as extrusion, injection molding, blow molding, thermoforming, and recycling, which require high temperatures, continuous production, and precise process control. On these lines, pneumatic and fluid control systems directly affect production speed, product quality, and energy efficiency. Properly selected air preparation and control solutions reduce downtime, lower maintenance costs, and improve process stability.

Why Is Compressed Air Critical in Plastics Production Lines?

In plastics plants, pneumatic cylinders, valves, vacuum equipment, conveying, and routing mechanisms are widely used. Moisture, particles, or oil in the air quality can lead to issues such as valve sticking, cylinder wear, sensor drift, and control errors. Therefore, clean, dry, and stable compressed air is critical for sustainable production.

- Stable process: Pressure fluctuations decrease and cycle times become more consistent.

- Higher quality: Critical parameters such as shape, dimensions, and surface quality become more consistent.

- Less downtime: Production losses due to failures and maintenance are minimized.

- Energy savings: Consumption decreases with proper regulation and leak management.

Applications

- Injection molding: Fast control in part removal, mold auxiliary movements, and automation systems

- Extrusion: Reliable pneumatic control in conveying, cutting, and routing processes along the line

- Blow molding: Stable performance in forming, vacuum, and fast open/close mechanisms

- Thermoforming: Stable production with precise management of vacuum and pressure control

- Packaging & palletizing: Durable and repeatable system control in high-cycle movements

Key Advantages

- Reliable air preparation (FRL): Extended equipment life through filtration and regulation

- Fast and precise control: Optimized cycle times with valve and actuator solutions

- Ease of maintenance: Fast service thanks to a modular and accessible design

- Focus on uninterrupted production: Reduced unplanned downtime and increased efficiency

Conclusion

In the plastics industry, competition is won through speed, quality, and cost management. The right pneumatic and fluid control infrastructure helps your production lines operate more consistently, improves energy efficiency, and contributes to lowering total operating costs.